An ultrafast process for the preparation of lithium metal-inorganic solid electrolyte interfaces

An ultrafast process for the fabrication of a Li metal-inorganic solid electrolyte interface

Energy & Environmental Science ( IF 38.532 ) Pub Date : 2021-06-24 , DOI. 10.1039/d1ee00759a

Hirokazu Kitaura, Eiji Hosono, Haoshen Zhou

abstract

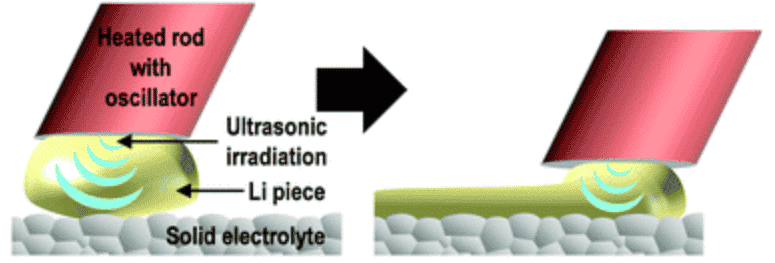

A lithium anode is expected to be applied to next-generation batteries using inorganic solid electrolytes (ISEs). When joining Li with ISEs, interfacial reactions often cause performance degradation and have been avoided. In this report, we demonstrate a new strategy for the ultrafast formation of a good interface between Li and ISEs, using a reactive process (ultrasonic-assisted fusion welding method). We found that ultrasonic irradiation helps in suitable interface formation between molten Li and ISEs, and the joining process finishes in just a few seconds. The obtained interface showed a low resistance and could be used under a high current density of 0.5 mA cm-2. The development of The development of prototype cells for next-generation batteries was promoted by this ultrafast process.

Broader context

Li metal, which has a large theoretical capacity (3860 mA h g-1) and a negative potential (-3.04 V vs. standard hydrogen potential), is regarded as the ultimate anode material. All-solid-state batteries using inorganic solid electrolytes (ISEs) and Li metal are expected to be next-generation batteries with high safety and high energy density. batteries with high safety and high energy density. Therefore, techniques to effectively bond Li metal to ISEs in a short time by a simple process are important in the research on Li-ion batteries. Therefore, techniques to effectively bond Li metal to ISEs in a short time by a simple process are important in the research on Li-ISE batteries. this report, we demonstrate a new strategy for rapidly joining Li metal and an ISE using ultrasonic waves - the ultrasonic-assisted thermal fusion bonding method. We found that ultrasonic irradiation helps in the interface formation between Li and the ISE, and the joining process finishes in just a few seconds. The obtained interface showed a low resistance and could be used under a high current density. The development of prototype cells was promoted by this ultrafast process. This technology, which easily creates an electrochemically favourable Li-ISE interface, liberates people from the hassle of Li and the ISE. This technology, which easily creates an electrochemically favourable Li-ISE interface, liberates people from the hassle of Li anode fabrication and will promote the realization of next-generation batteries and the utilization of electric vehicles.

An ultrafast process for the preparation of lithium metal-inorganic solid electrolyte interfaces

Lithium anodes are expected to be used in the next generation of batteries using inorganic solid electrolytes (ISE). When combining Li with ISE, interfacial reactions typically lead to performance degradation and have been avoided. In this report, we demonstrate a new strategy to form a good interface between Li and ISE ultra-fast using a reactive process (ultrasound-assisted fusion welding method). We found that ultrasonic irradiation helps to form a suitable interface between molten Li and ISE and that the joining process takes only a few seconds to complete. The obtained interface shows low resistance and can be used at a high current density of 0.5 mA cm-2. This ultrafast process facilitates the development of prototype cells for next-generation batteries.

Lithium metal, with its large theoretical capacity (3860 mA h g-1) and negative potential (-3.04 V vs. standard hydrogen potential), is considered the ultimate anode material. All-solid-state batteries using inorganic solid electrolyte (ISE) and lithium metal are expected to be the next generation of batteries with high safety and high energy density. Therefore, the technique of efficiently bonding lithium metal to ISE through a simple process in a short time is very important in the research of Li-ISE batteries. However, conventional methods require long and tedious processes. In this report, we demonstrate a new strategy for rapidly bonding lithium metal to ISE using ultrasound, the ultrasound-assisted thermal fusion method. We found that ultrasonic irradiation aids in the formation of the interface between fused lithium and ISE, and the joining process takes only a few seconds to complete. The obtained interface shows low resistance and can be used at high current densities. This ultrafast process facilitates the development of prototype batteries. The technology makes it easy to create electrochemically favorable Li-ISE interfaces, freeing people from the hassle of manufacturing lithium anodes, and will facilitate the realization of next-generation batteries and the adoption of electric vehicles.

Note: The Chinese translation is done by a computer program, please refer to the original.

Source:Energy & Environmental Science

Related Products

FCE10 ferroelectric material test equipment

Japan Toyo Technica high frequency low noise ferroelectric evaluation system

4990EDMS-120K high frequency impedance analyzer

Toyo High Frequency Impedance Measurement System for All-Solid-State Electrolytes*, Japan