Coating Process-Coating

What is coating?

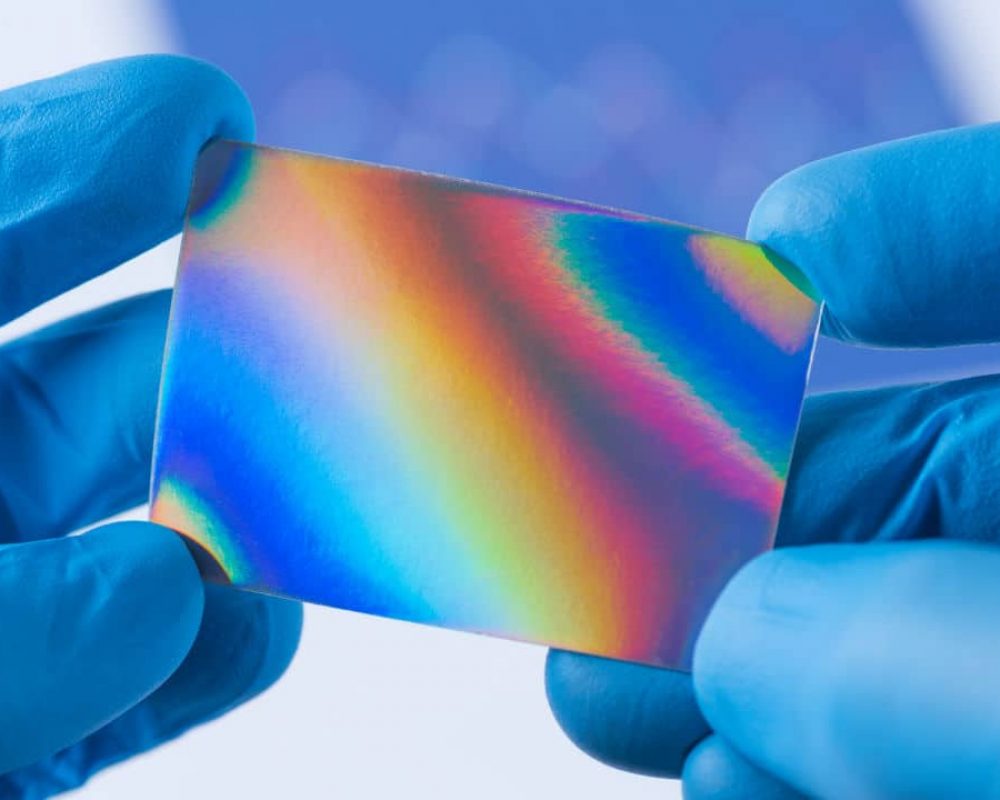

Thin film deposition (Plating) is the process of forming and depositing a thin film coating on the substrate material.Deposition of thin films of various materials on substrates is one of the important means of micro and nano processing.Films have many different properties that can be used to modify or improve certain elements of a substrate's performance. For example, transparent, durable and scratch resistant; increase or decrease electrical conductivity or signal transmission, etc.Thin film deposition thicknesses range from the nanometer to the micron scale.

The commonly used thin film deposition processes arePhysical Vapor Deposition (PVD)withChemical Vapor Deposition (CVD).

Our Capabilities

Thermal evaporation deposition

(thermal evaporative)

Resistance heating evaporation, electron beam thermal evaporation

Atomic layer deposition

(ALD)

Plasma Chemical Vapor Deposition (PECVD)

RF power: 0-600W, process temperature: 350°C; uniformity ≤±5%

Low Pressure Chemical Vapor Deposition (LPCVD)

Ion beam sputtering

(IBS)

Coating Materials

Coating Materials

Metal Materials

Titanium (Ti), aluminum (Al), nickel (Ni), gold (Au), silver (Ag), chromium (Cr), platinum (Pt), copper (Cu), titanium tungsten (TiW90), palladium (Pd), zinc (Zn), molybdenum (Mo), tungsten (W), tantalum (Ta), niobium (Nb)

Coating Materials

Non-metallic materials

Silicon (Si), silicon dioxide (SiO2), silicon nitride (SiNx) Aluminum oxide (Al2O3), hafnium dioxide (HFO2), magnesium fluoride (MgF2), indium tin oxide (ITO), tantalum pentoxide (Ta2O5)

Production Process

1. Preliminary offer

Send your drawings and requirements to our development manager for an initial quote

2. Program determination

We will optimize and determine the plan and quotation based on the drawings and requirements

3.Production and quality control

We will select the best equipment for your product and take full responsibility for your product to meet our standards.

4. Delivery on time

Delivered to you on time

Quality Inspection

Detection means

Optical microscopy (Microscopy)

Detection means

Profilometer (Profilometer)

Detection means

Sheet Resistance Measurement

Detection means

Hall measurement )

Cases we have done

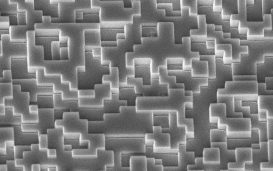

Micro and nano structures

Diffractive Optical Elements (DOE)

Micro and nano structures

Superlenses (METALENSES)

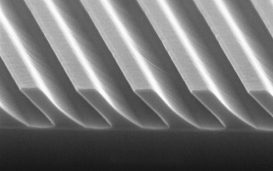

Micro and nano structures

Diffraction grating (line point, shine, tilt)

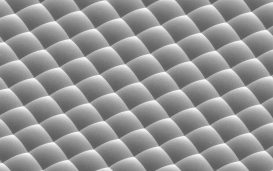

Micro-Nano Architecture

Microlens arrays

Applications

Micro and Nano Applications

Microlens arrays

Micro and Nano Applications

Line grid polarizer

Micro and Nano Applications

Sensors

Micro and Nano Applications

Flexible Electronics

Micro and Nano Applications

Anti-reflective film

Micro and Nano Applications

OLED Panel

Micro and Nano Applications

Microfluidic channels/chips

Micro and Nano Applications

AR Optical Waveguide

Our Advantages

Full process coverage

Cooperate with many domestic experiments and have different processing technology reserve from 100um-5nm

High standard quality control

We adhere to the spirit of 6sigma service, choose the most suitable experimental platform, process, personnel, materials for processing

Quick Response

From idea to implementation, our experts will provide professional advice and ongoingTrackingServices

Save time and worry

Turnkey service, from principle implementation, drawing design, raw material procurement, to finished product processing

Contact Us

Get ready

Did you realize your idea?

You design the future, we build it.