Etching Process - Etching

What is etching?

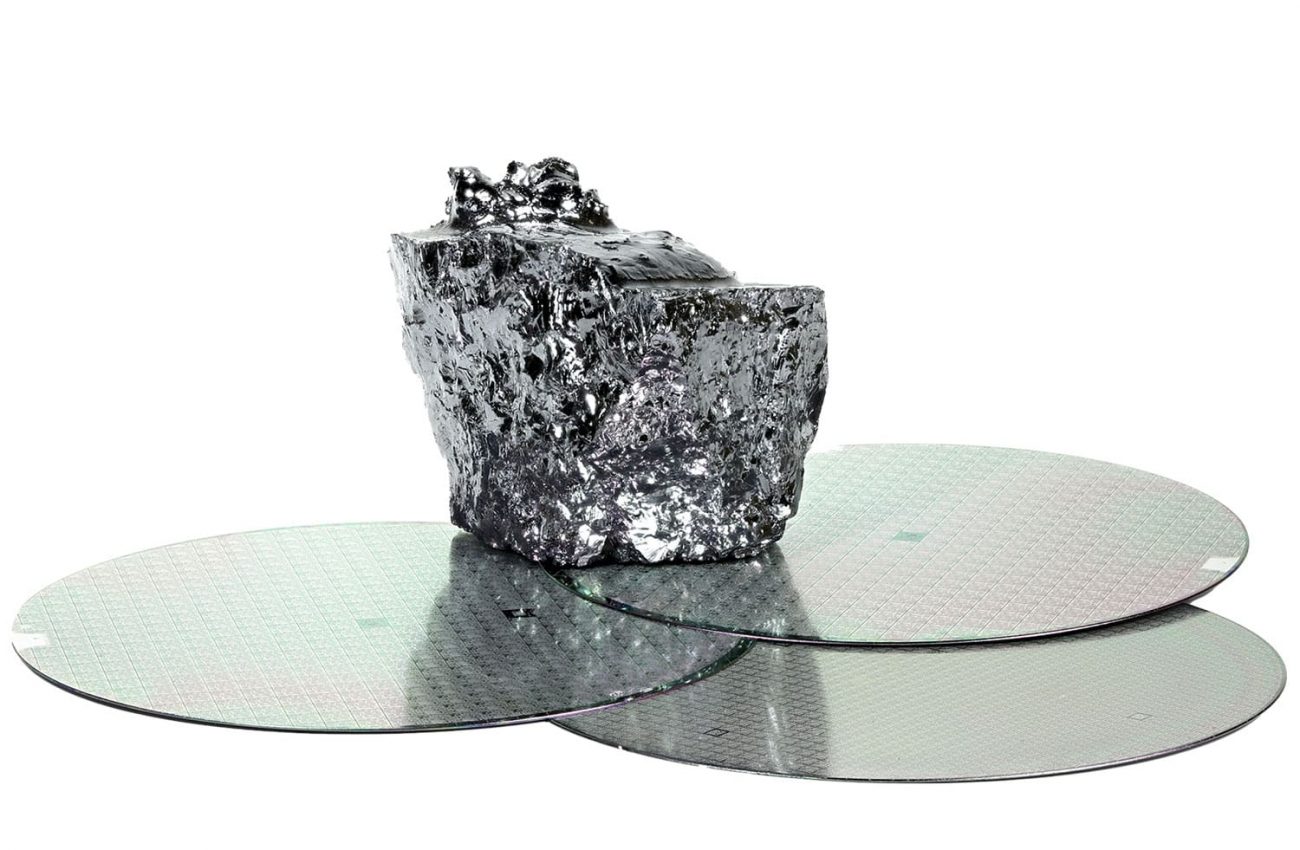

Etching in micro and nano processing technology is the process of removing unnecessary materials attached to the wafer surface using chemical or physical methods. The main steps of semiconductor manufacturing include photolithography, etching, and thin film deposition, which are continuously cycled to create complex and fine circuit structures.

Our Capabilities

Etching process

Reactive ion etching

(RIE-Reactive Ion Etching)

The most widely used and most capable technology for micro and nano processing, etching Si, SiO₂, SiNx, etc.

Etching process

Deep Reactive Ion Etching

(DRIE-Deep Reactive Ion Etching)

Etching uniformity UN<3%; deep Si etching rate 2-10um/min; Sio2 and SiNx etching rate 20-150nm/min

Etching process

Focused Ion Beam Etching

(FIBE-Focused Ion Beam Etching)

Micro and nano processing of materials and devices such as etching, deposition and doping

Etching process

Ion beam sputter etching

(IBE-Ion Beam Etching)

For metals or other substances that are difficult to etch

Etching process

Inductive/capacitive coupled plasma etching

(ICP/CCP-Inductively/capacitance Coupled Plasma)

Etching GaN, GaAs, InP and other materials

Etching process

Wet etching (wet etching)

Can handle 2inc-8inc inorganic and inorganic cleaning, as well as conventional acid and alkali corrosion

Etching materials

Etching materials

Common etching materials

Etching materials

Wet etching solution

Production Process

1. Preliminary offer

Send your drawings and requirements to our development manager for an initial quote

2. Program determination

We will optimize and determine the plan and quotation based on the drawings and requirements

3.Production and quality control

We will select the best equipment for your product and take full responsibility for your product to meet our standards.

4. Delivery on time

Delivered to you on time

Quality Inspection

Detection means

Optical microscopy (Microscopy)

Detection means

Profilometer (Profilometer)

Detection means

Sheet Resistance Measurement

Detection means

Hall measurement )

Cases we have done

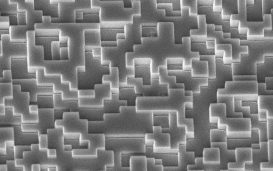

Micro and nano structures

Diffractive Optical Elements (DOE)

Micro and nano structures

Superlenses (METALENSES)

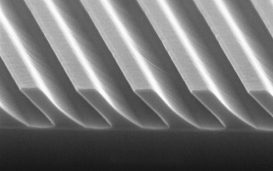

Micro and nano structures

Diffraction grating (line point, shine, tilt)

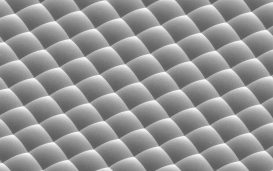

Micro-Nano Architecture

Microlens arrays

Applications

Micro and Nano Applications

Microlens arrays

Micro and Nano Applications

Line grid polarizer

Micro and Nano Applications

Sensors

Micro and Nano Applications

Flexible Electronics

Micro and Nano Applications

Anti-reflective film

Micro and Nano Applications

OLED Panel

Micro and Nano Applications

Microfluidic channels/chips

Micro and Nano Applications

AR Optical Waveguide

Our Advantages

Full process coverage

Cooperate with many domestic experiments and have different processing technology reserve from 100um-5nm

High standard quality control

We adhere to the spirit of 6sigma service, choose the most suitable experimental platform, process, personnel, materials for processing

Quick Response

From idea to implementation, our experts will provide professional advice and ongoingTrackingServices

Save time and worry

Turnkey service, from principle implementation, drawing design, raw material procurement, to finished product processing

Contact Us

Get ready

Did you realize your idea?

You design the future, we build it.