FCE10 ferroelectric material test equipment

Japan Toyo Technica high frequency low noise ferroelectric evaluation system

With the strong development of technology, low-power non-volatile memories, including magnetoresistive random access memories and ferroelectric random access memories (FRAM), have been integrated with low-power microcontrollers for IoT devices). FRAMs with ferroelectric Pb(ZrTi)O3 (PZT) films are much lower than flash memory. Typically, thickness scaling in ferroelectric films reduces the size of ferroelectric capacitors and thus reduces power consumption. However, PZT films are known to lose their ferroelectricity when the thickness is thinned to less than 100 nm. In addition, PZT films with noble metal electrodes are not fully compatible with semiconductor processes. Several ferroelectric materials have been reported, thus far replacing conventional ferroelectric materials. The ferroelectric HfO2 film reported in 2011 has the advantage of being able to maintain its ferroelectricity below 3 nm. The fabrication process can be done at low temperatures by a fully compatible semiconductor process. In addition, ferroelectric Al1-xScxN films with a residual polarizability (Pr) of more than 100 μC cm-2 were reported in 2019.26,27) A high Pr is also attractive because the electrodes of ferroelectric capacitors can be further reduced to obtain higher bulk densities, and current induction during write and read operations can easily resist noise.

One of the problems of Al1-xScxN films is the relatively high coercivity field (EC), which depends on the composition of the Sc atoms (x) in Al1-xScxN films and is controllable. Advantages in terms of terminology The fibrinite-type structure of Al1-xScxN in the range 0 < x < 0.46 is a stable phase polarity in the Al-Sc-N system (for the nitride case, metal plane or N plane) and we can expect deposition of Al1-xScxN films with self-polarized c-axis orientation in the thin film region as well.

We have reported some thickness-dependent ferroelectric properties down to 20 nm. we extended our work to characterize the thickness effect of Al0.78Sc0.22N films to the degree of crystal orientation and ferroelectric properties in the films. The n+Si substrates with a doping density of 3 × 1018 cm-3 were chemically cleaned with a solution of sulfur peroxide mixture (SPM, H2SO4/H2O2= 3:1) and then impregnated with dilute HF (1%). TiN bottom electrodes were sputter deposited on the substrates at 300 W RF power on Ti targets with Ar and N2 gas flow rates of 4 and 6 sccm, respectively, at a pressure of 0.22 Pa. Then, the Al0.78Sc0.22N films were deposited from the Al0.57Sc0.43 target by DC sputtering at 300 W with Ar and N2 gas flows of 5 and 10 sccm, respectively, at a pressure of 0.7 Pa. The compositions of the Al0.78Sc0.22N films deposited under these conditions were determined by X-ray photoelectron spectroscopy. We varied the deposition time of the Al0.78Sc0.22N films to form films with a thickness of 10-47 nm. Another TiN layer was deposited in situ on the Al0.78Sc0.22N film. All deposition processes were kept at a constant temperature of 400 °C. The top TiN layer was photolithographically patterned by wet etching using an ammonium peroxide mixture (APM, NH4OH: H2O2:H2O = 1:5:5) to form the top electrode. Finally, the aluminum back contact is formed by thermal evaporation. We have shown that the capacitors have almost the same leakage current in the applied electric field, indicating that the defect density size is the same inside the film and near the interface. The crystallization and orientation of the grains in the film were evaluated by X-ray diffraction (XRD) in out-of-plane and wiggle curve configurations. The X-ray source was CuKa with a divergence angle of 0.04°. Capacitance-voltage (CV) characteristics were obtained using an Agilent E4980A LCR meter with a small signal amplitude of 50 mV at 100 kHz. The polarization-voltage (PV) characteristics of the capacitor were measured at 10 kHz using TOYO's FCE10 series setup.

The main focus of this paper is on the thickness scaling of the sputter-deposited unpolarized Al0.78Sc0.22N films that have been examined for their ferroelectric properties. The c-axis oriented films were confirmed by X-ray swing curve measurements with films as thin as 10 nm. Ferroelectric-type hysteresis and no-polarization behavior were observed from capacitance measurements even at thicknesses of 20 nm. Residual polarization (Pr) showed gradual degradation at thicknesses less than 35 nm. Switching (SW) cycling tests reveal a wake-up effect of the film, especially for thicker films than 35 nm.

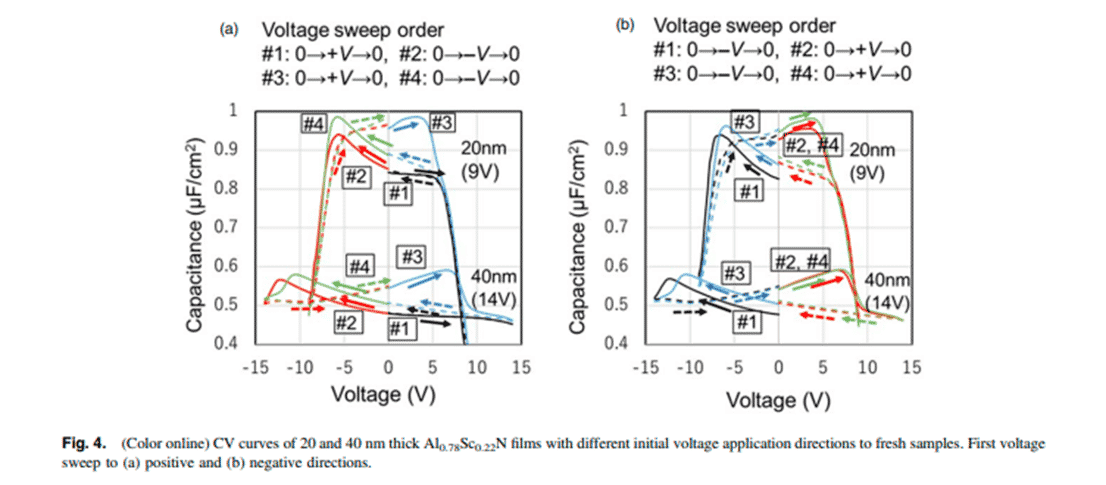

We performed polarity-dependent CV measurements on 20 and 40 nm thick Al0.78Sc0.22N films, as shown in Figure 4. Initially applied to the samples, there was almost no difference in capacitance between the top and bottom scans [Fig. 4(a)]. Subsequently, by applying a negative voltage to the top electrode, a gradual increase in capacitance was observed accompanied by a sudden drop at a certain voltage. The following voltage applied in the positive direction shows ferroelectric switching (SW) behavior. On the other hand, when the initial voltage applied to the fresh sample is set to the negative direction, as shown in Figure 4(b), we see a sudden drop in capacitance, indicating that the film is switched. From these measurements, we can conclude that the Al0.78Sc0.22N film has self-polarized in the direction from the surface to the substrate.

By Sung-Lin Tsai,Takuya Hoshii1,HitoshiWakabayashi1,Kazuo Tsutsui,Tien-Kan Chung ,Edward Yi Chang,and KuniyukiKakushima

Institution: School of Engineering, Tokyo Institute ofTechnology, 4259 S2-20, Nagatsuta, Midori-ku, Yokohama 226-8502, Japan 2International College of Semiconductor Technology, National Chiao TungUniversity, 1001 University Road, Hsinchu 30010, Taiwan ROC 3 Institute ofInnovative Research, Tokyo Institute of Technology, 4259 S2-20, Nagatsuta,Midori-ku, Yokohama 226-8502, Japan 4 Department of Mechanical Engineering, National Chiao Tung University, 1001 University Road, Hsinchu 30010, Taiwan ROC

Published: Received October 16, 2020; revised March 7, 2021;accepted March 16, 2021; published online April 1, 2021

Journal: Japanese Journal of Applied Physics 60, SBBA05(2021)

Article source website: On the thickness scaling of ferroelectricity inAl0.78Sc0.22N films ((https://iopscience.iop.org/article/10.35848/1347-4065/abef15/pdf)

Japan Toyo Technica high frequency low noise ferroelectric evaluation system