Micro-Nano Processing| Protein-based Micro-Nano Device Chip Fabrication

In recent years, due to the development of portable devices. People pay more attention to the flexibility of electronic devices. Especially in the wave of wearable devices triggered by the Internet era, people expect flexible electronic devices. Based on the above, protein materials are not only very soft, but also have good biocompatibility. Therefore, electronic devices based on protein materials have naturally become a hot topic of research. On the other hand, there is a desire to implant electronic devices into animals that can sense and process information. Therefore, optical or electronic chips with biocompatibility are favored by researchers.

Since the first successful use of spider silk to induce cell expulsion by humans in 1911, this method of inducing cell division and growth has been called cell patterning. As a simple means of simulating experiments, cell patterning technique has two advantages of simplifying experimental systems and simulating three-dimensional cellular environments. As a result, cell patterning has been widely used and many results have been commercialized. For example, in the fields of tissue engineering, drug screening, and trauma therapy.

In recent years, the urgent needs of human in the field of biological health have led to an increasing interest in natural biomolecular materials (e.g., proteins, sugars, peptides, RNAs, cellulose, etc.), and human hopes to use natural macromolecular materials without chemical modification to minimize the process and complexity and retain the environmentally friendly properties of natural macromolecular materials. The research of functionalized devices using unmodified natural macromolecule materials is also being carried out. On the other hand, efforts are also being made to directly exploit the intrinsic properties of biomolecular materials, such as mechanical, electrical, and optical properties, in order to prepare biopolymer-based materials and devices. For example, highly sensitive sensors that can be used for the detection and sensing of heavy metal ions have been prepared by exploiting the base pair complementary properties of deoxyribonucleic acid; sensors that can be used to monitor changes in temperature, humidity, and PH values have been prepared by exploiting the response properties of protein materials to the environment; and optical waveguide-like devices have been prepared by exploiting the mechanical properties of cellulose.

The means to achieve materialization-device-functionalization of protein-based are:

1. Preparation of protein-based optical waveguides based on femtosecond laser direct writing technology

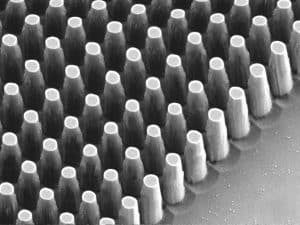

Femtosecond laser direct writing technique was used to process waveguide-like devices on protein-based materials and perform through-light tests to demonstrate that protein materials can be used to prepare waveguide-like devices. And then it was demonstrated that the prepared waveguide-like devices with good device surface morphology were prepared, and the through-light tests of waveguide devices were performed.

2. Preparation of protein material films based on UV lithography lithography

We built our own UV lithography system to prepare protein films using UV lithography lithography. The protein-based periodic micro-nano-stripe devices were prepared using the mask version, and they were subjected to grating tests to demonstrate whether the morphology and stripe quality of periodic micro-nano-stripe can be used as micro-nano grating devices. And then, the periodic stripes were used as substrates and co-cultured with cells to demonstrate that the periodic stripes can induce cell growth or alignment, thus enabling cell patterning. This work focuses on the device realization of protein hydrogel materials from materials by UV lithography.

3. Carbon dot-protein functionalized device preparation based on UV lithography

Using the UV lithography system built in the previous paper, the carbon dot-protein hybrid material was mixed into a composite hydrogel material, and the hybrid material film was prepared later. And the hybrid material films were used for visible light catalysis functionalization exploration.

We offer fastMEMS device / micro and nanostructure processing design services, Feel free to leave a message to inquire.

Related Products

Micro-Nano Processing丨Nano Imprinting (NIL) Subcontracting

Nanoimprinting (NIL) Nanoimprinting (NIL) Yes

Micro-Nano Optics 丨Metalenses processing

Metalenses with 10 years of experience in micro and nano optics

Related Reading

Micro and Nano Processing | Thin Film Preparation - CVD

Thin film preparation-deposition Chemical methods can be created to produce films with excellent homogeneity and

Micro and Nano Processing | MEMS Fine Processing (IV)

Micro and Nano Processing | MEMS Fine Processing (IV) 1.3 Photolithography

Micro and Nano Processing | MEMS Research Direction

Micro and Nano Processing | MEMS research direction classification MEMS research self