Diffractive Optical Elements (DOE)

What is a diffractive optical element

Diffractive Optical Elements (DOE) are phase elements, which are based onThe theory of optical wave diffraction utilizes a continuous relief-type or step-type structure etched on the substrate to obtain extremely high diffraction efficiency.Its small size, light weight, design freedom, imagingGood quality, broad application prospects in the fields of optical imaging, optical data storage, laser technology, biomedicine, etc.

There are three types of functions:Beam shaper, ,Beam splitterandDiffusers(also known as homogenizer)

DOE Application Areas

Laser material processing

Shaping and beam splitting of laser beams in welding, cutting, scribing, soft welding and drilling processes

Applications

Photolithography and holographic illumination

Homogenization of projection beams in mask projection systems, structured pupil illumination, uniform field illumination of vertical and highly inclined planes

Applications

Biomedical Equipment

Diffractive optics for medical laser therapy and diagnostic instruments

Applications

Optical Sensors

Distance and position sensors, motion detection

Applications

LIDAR

Optical distance and speed measurement using laser beams

Applications

Communication

Beam splitters, wavelength selection and silicon optics applications

Our Capabilities

Processes

Lithography (Photolithography)

Electron beam lithography (EBL)UV lithographyProximity/contact lithography, stepper lithography, etc.

Processes

Two-photon 3D printing (Two-photonpolymerization)

Processes

Etching (Etching)

Focused Ion Beam EtchingDeep reactive ion etching, inductively coupled plasma etching, ion beam sputtering etching, etc.

Processes

Nanoimprinting(Nanoimprint lithography)

Nano-thermal embossing, UV-curable embossing, micro-contact printing (soft etching)

Processes

Coating

Magnetron sputteringAtomic layer deposition.Ion beam sputtering, ,Plasma chemical vapor deposition, etc.

Processes

Electroforming (LIGA)

Production Process

1. Preliminary offer

Send your drawings and requirements to our development manager for an initial quote

2. Program determination

We will optimize and determine the plan and quotation based on the drawings and requirements

3.Production and quality control

We will select the best equipment for your product and take full responsibility for your product to meet our standards.

4. Delivery on time

Delivered to you on time

Cases we have done

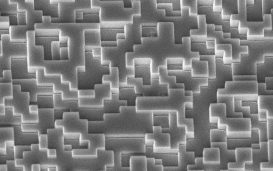

Micro and nano structures

Diffractive Optical Elements (DOE)

Micro and nano structures

Superlenses (METALENSES)

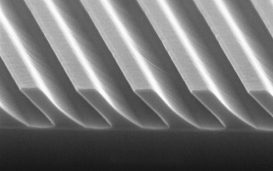

Micro and nano structures

Diffraction grating (line point, shine, tilt)

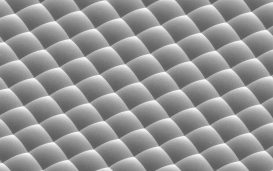

Micro-Nano Architecture

Microlens arrays

Test characterization

Detection means

Optical microscopy (Microscopy)

Detection means

Profilometer (Profilometer)

Detection means

Sheet Resistance Measurement

Detection means

Hall measurement )

Our Advantages

Full process coverage

Cooperate with many domestic experiments and have different processing technology reserve from 100um-5nm

High standard quality control

We adhere to the spirit of 6sigma service, choose the most suitable experimental platform, process, personnel, materials for processing

Quick Response

From idea to implementation, our experts will provide professional advice and ongoingTrackingServices

Save time and worry

Turnkey service, from principle implementation, drawing design, raw material procurement, to finished product processing

Contact Us

Get ready

Did you realize your idea?

You design the future, we build it.